Hot pressing ironing tape style.

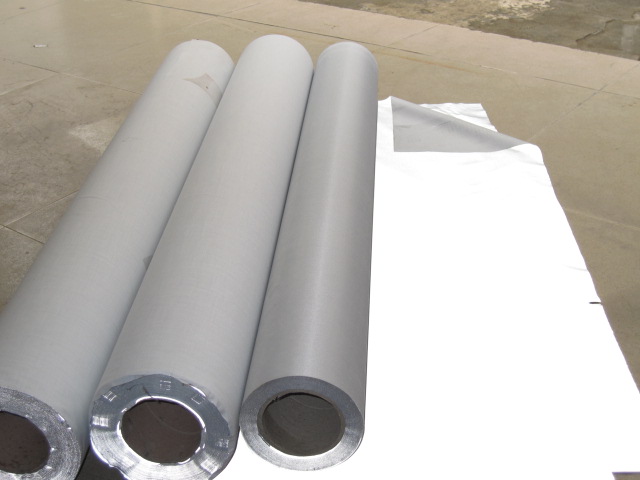

size:width 1meters,lenght 5meters. 1m=100cm=3.28 ft.

Lenght can continue to buy, do not cut.

Reflective fabric used for occupational safety; also used to make decorative reflective products.

Folded packaging, more than 10 meters rolled up to sent.

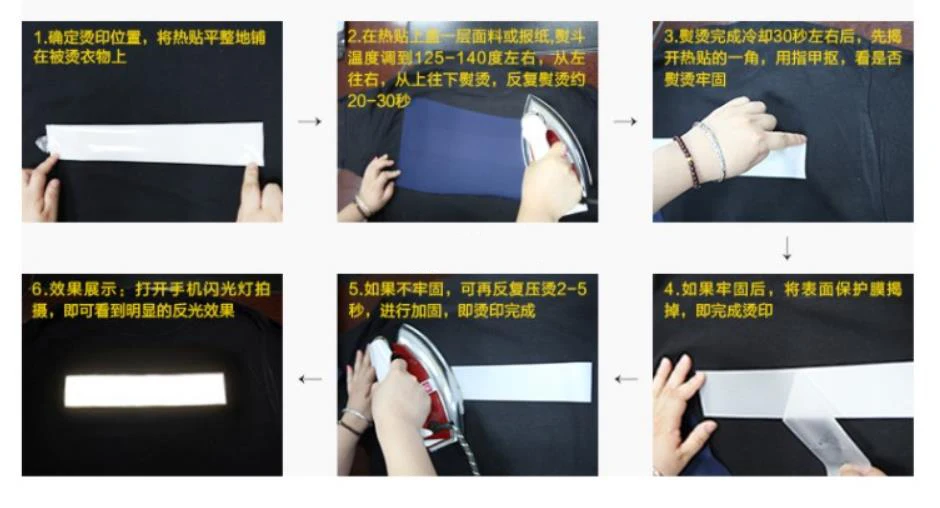

How to use: Place the side of the plastic film up and flat on the burnt clothing, then cover the hot post with a layer of newspaper or cloth, then iron it with an iron above 125 degrees, first iron from top to bottom. Once you have burned it, stick the hot sticker on the clothes and then iron it for 20-30 seconds. After ironing, wait for a little cooling, first tear off the corner of the hot sticker, use the nail file to see if it is firm. If it is firm, remove the protective film from the surface and finish ironing. If it is not strong, it can be ironed several times.

Precautions:

1. Hot stamps are not applicable to nylon substrates and any substrates that have been treated with water;

2. Regardless of the processing method, the processor must test the operating conditions of each method and different substrates before use to achieve the best fastness and appearance;

Third, the recommended process conditions: 130 degrees to 160 degrees, plane pressure > 0.5kg / cm2, pressing time 3 ~ 4 seconds or line pressure 2kg / cm2, pre-heating time 3 ~ 4 seconds (plane pressure is for flat or flat Thermal bonding equipment, line pressure is for roller type hot bonding equipment.)

Fourth, the blanching temperature should not be too high, and the pressing time should not be too long, so as to prevent the hot melt adhesive from being sufficiently absorbed by the substrate, and the fastness is lowered;

5. For hot-rolling products that need to be evaluated for washing fastness or further improve the fastness, it is recommended to perform another pressing operation after peeling off the protective film: the temperature should be lowered by about 40 degrees, other pressures and pressures. The hot time is unchanged, but the cleaning of the hot bonding equipment must be ensured, otherwise the brightness of the hot post will be seriously affected;

Sixth, after blanching, it is necessary to cool the protective film after cooling to the natural room temperature. When tearing the protective film, tear it off as much as possible at 180 degrees. It should not be stopped in the middle to avoid the occurrence of pause marks and affect the appearance;

![]()