$8,724.00

100 in stock

Description

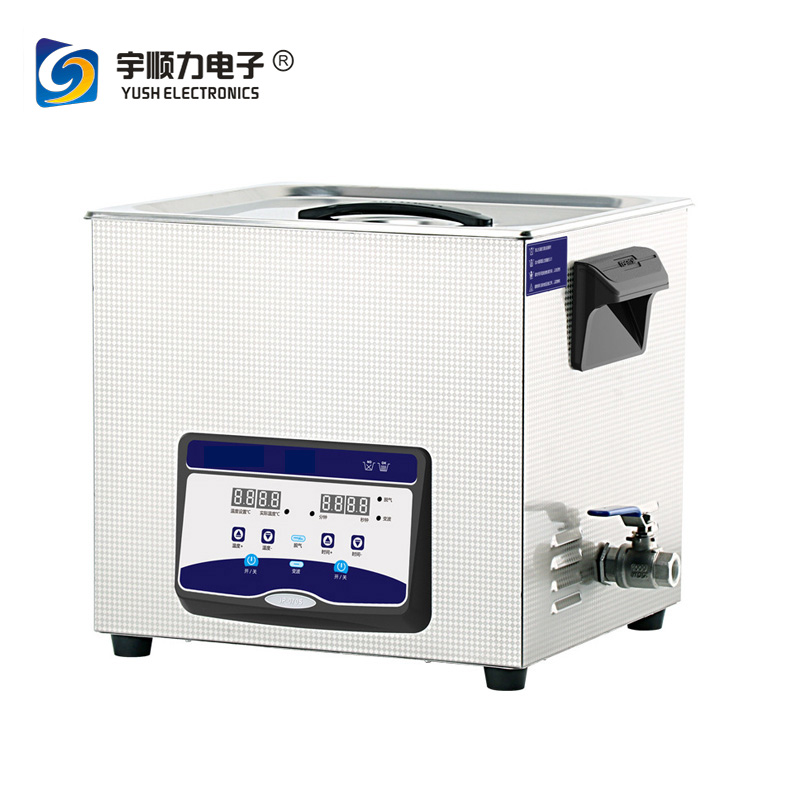

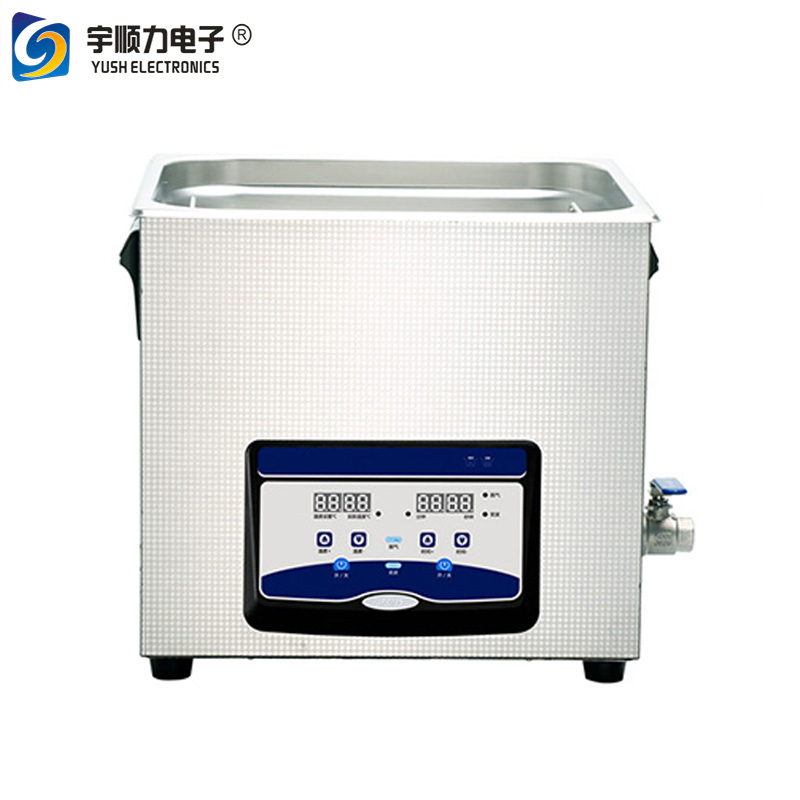

- Brand Name: yushunli

- Origin: CN(Origin)

- Type: Industrial Computer Accessories

- Model Number: YS-070S

- Package: Yes

- Ultrasonic frequency: 40KHz

- Ultrasonic power: 420W (7 shocks)

- capacity: 20L

- heating power: 300W (CNC heating)

- Liner material: Stainless steel (SUS304)

- Liner size: 330*300*200mm

- External dimensions: 400*330*330mm

- Package dimensions: 465*400*415mm

- time control: Digital control (1-30 minutes)

- power supply: AC100-120V,AC220-240V

- weight: N.W.10.2KG,G.W.11.3KG

YS-070Sultrasonic cleaning machine features:

1. Digital display: The digital control ultrasonic cleaning machine is superior to the mechanical rotary button control, easy to operate, accurate in time, accurate and durable.

2, heating function: 0-65 ° heating temperature freely set.

3, long cleaning standby time: 0-60 minutes long cleaning time.

YS-070S ultrasonic cleaning machine for a range of applications:

Applicable departments: electronic workshops, industrial and mining enterprises, laboratories, hospitals, watch shops, optical shops, jewelry stores, mobile phone repair shops, families, etc.

Applicable cleaning items: electronic products, laboratory supplies, office supplies, household goods, computer motherboards and accessories, glassware, circuit boards, auto parts, hardware parts, medical equipment, dentures and dental instruments, watches, glasses, jewelry, golf Balls, razors, coins, micro-chapters, cutlery, bottles, fruits, etc.

YS-070S ultrasonic cleaning machine cleaning operation process:

1. Add tap water in the cleaning tank. The water level is guaranteed to be higher than or equal to 3/4 of the height of the tank in the cleaning tank. The electric heating is started, and the ultrasonic wave is started to degas. When the water temperature is about 40 degrees, the specified amount of ultrasonic special cleaning agent is added. The parts are cleaned when the water temperature reaches 55 to 60 degrees.

2. Disassemble the parts to be cleaned as much as possible. Use high-pressure water gun, wire brush, blade or other tools to manually pre-treat the soil, heavy oil and heavy carbon on the surface of the parts to ensure the service life of the cleaning fluid. And the speed and effect of cleaning.

3. Put the parts to be cleaned into the cleaning tank, and do not overlap the parts to ensure that the parts are completely submerged by the cleaning liquid.

4. Start the ultrasonic wave, generally clean it for 40~60 minutes. After cleaning, turn off the ultrasonic wave and take out the parts for post-processing.

5. Remove the residue on the surface of the parts with a high-pressure water gun, and remove the residue in the tunnel with an air compression gun. Parts that require rust prevention are treated separately. In order to improve the cleaning effect, the cleaning time of the parts in the cleaning liquid can be appropriately extended when time permits. In the actual operation process, in order to improve the cleaning efficiency, the process flow with disassembly and cleaning can be adopted.

Ultrasonic cleaning principle knowledge:

Mainly through the transducer, the sound energy of the power ultrasonic frequency source is converted into mechanical vibration, and the ultrasonic wave is radiated to the cleaning liquid in the tank through the cleaning tank wall. Due to the radiation of the ultrasonic waves, the microbubbles in the liquid in the tank can be kept vibrated by the action of the sound waves. The adsorption of the dirt and the surface of the cleaning member is destroyed, causing fatigue damage of the dirt layer to be rejected, and the vibration of the gas type bubble scrubs the solid surface.

Comparison of the effect before and after cleaning: